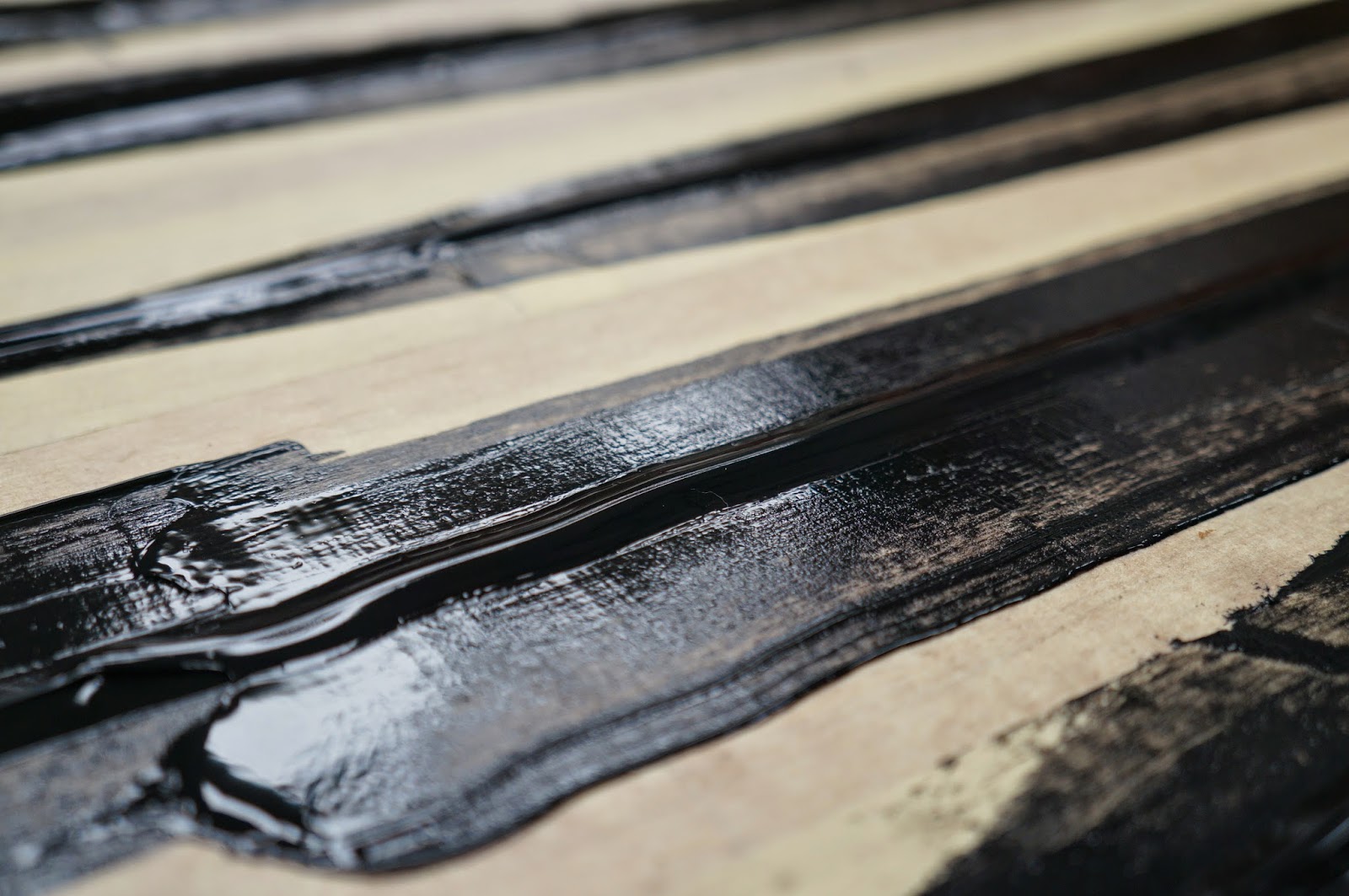

Pealing all the sticky masking off wasn't very picturesque but did leave nice clean lines of caulking ready to slice off with a sharp chisel.

The next step was sanding, the majority of which we used the air powered random orbital with 80 grit discs, using a sanding block to get in to the edges.

A very dusty job but with a quick hoover up the results are very satisfying.

One of the first jobs I did before starting the decking was to fit bits of scrap ply up against the inside of each skylight opening. I used acrow props inside supported from the keel not only for safety but it was also practical to have somewhere to put cumbersome tools, and employees.