A very sticky process indeed, working in a team of four we used an air powered sausage gun to apply Sabadeck to the thoroughly prepared marine ply substrate and the underside of our teak strips. A notched spreader was used to ensure a good even coat of glue was applied before laying, spacing and screwing each plank in position.

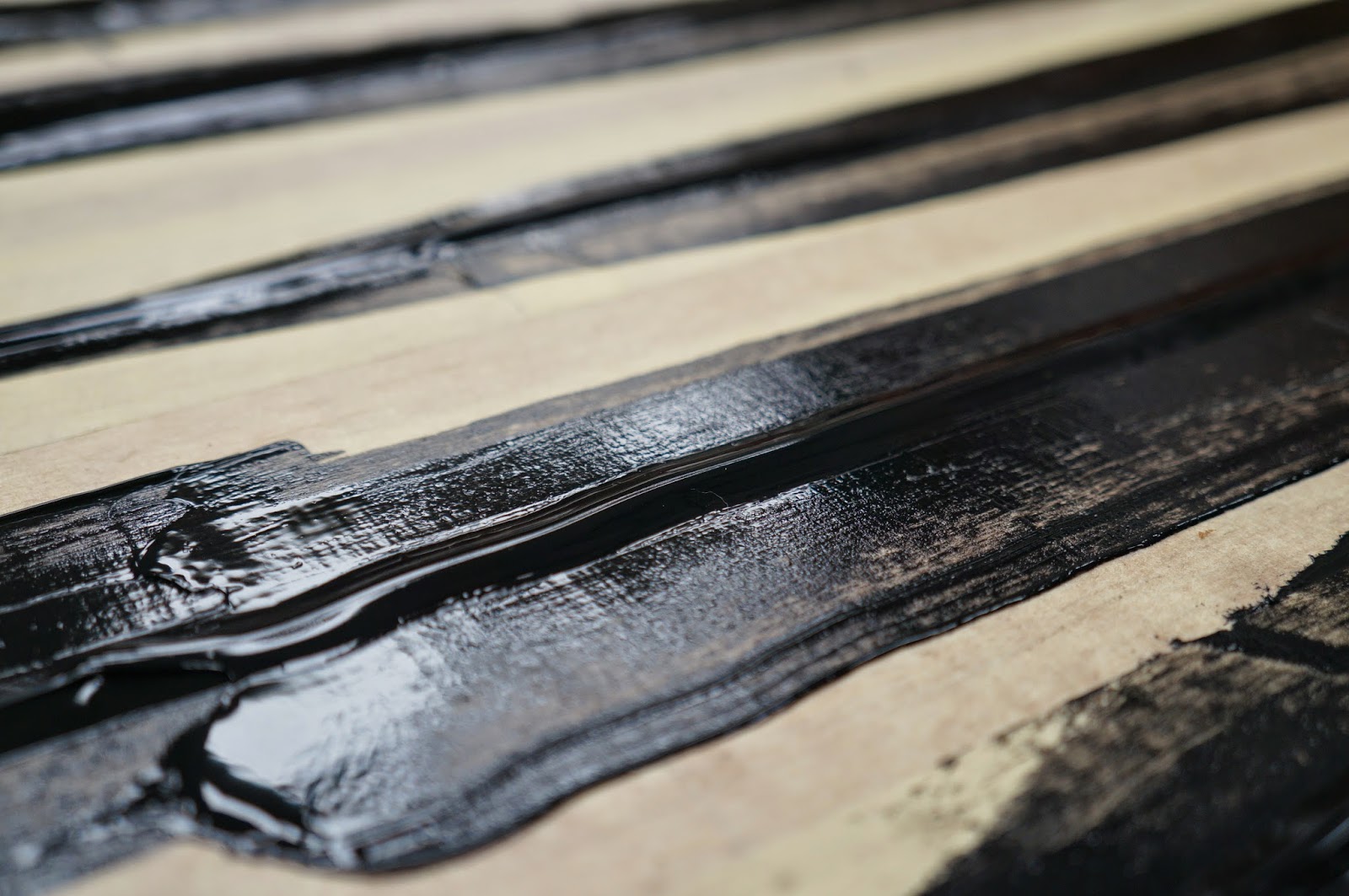

We ditched the air gun in favour of a more controllable hand operated sausage gun for the final stage of the Saba adhesive system, the imaginatively named Sabacaulk, which we applied with a fine nozzle filling from the bottom upwards in order to minimise the chance of air pockets.

A flat spreader was modified to provide a 2mm arc over each seam and carefully dragged over the 100 meter plus of caulking. A process neatly perfected by the time we had finished.

The Saba decking system was chosen by recommendation of Robbins Timber who supplied pretty much everything needed for this project. I found useful information regarding quantity calculations, application methods and drying times on both their website and Saba's

No comments:

Post a Comment